Our school district PR guy came to my class last week to take pics... Heres the scoop. He took several great pics, most of which I've posted here but you can see the entire album on the Districts Facebook page here:

District 55 Tech Class

Without further ado, here they are.

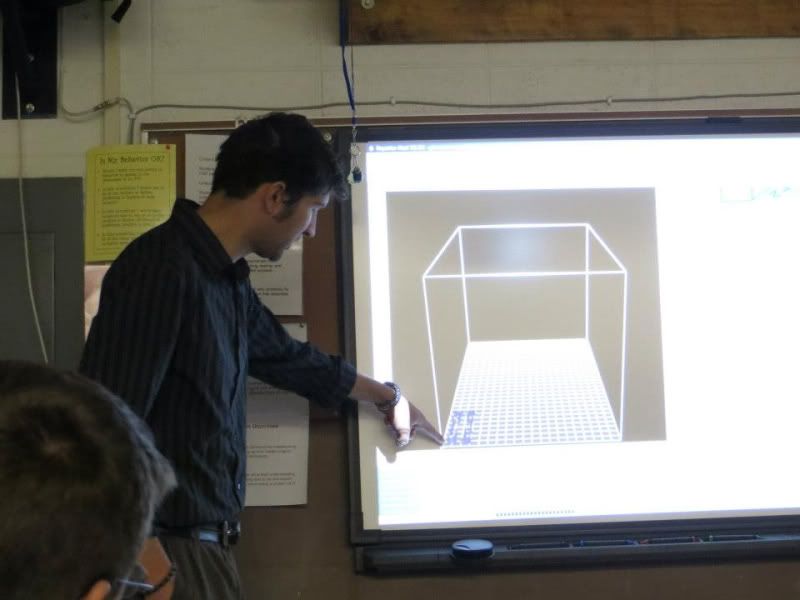

Students finishing up their Sketchup projects. Yes, we have ancient computers. When I started teaching here almost 4 years ago, I only had TWO, so I'm not going to complain!

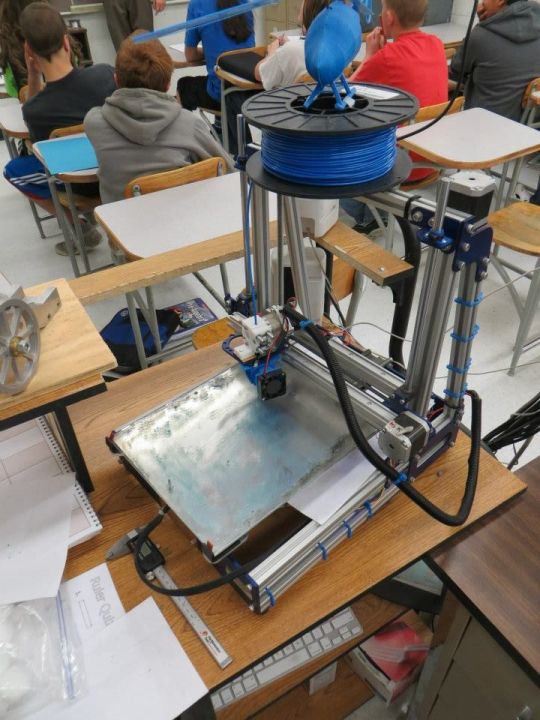

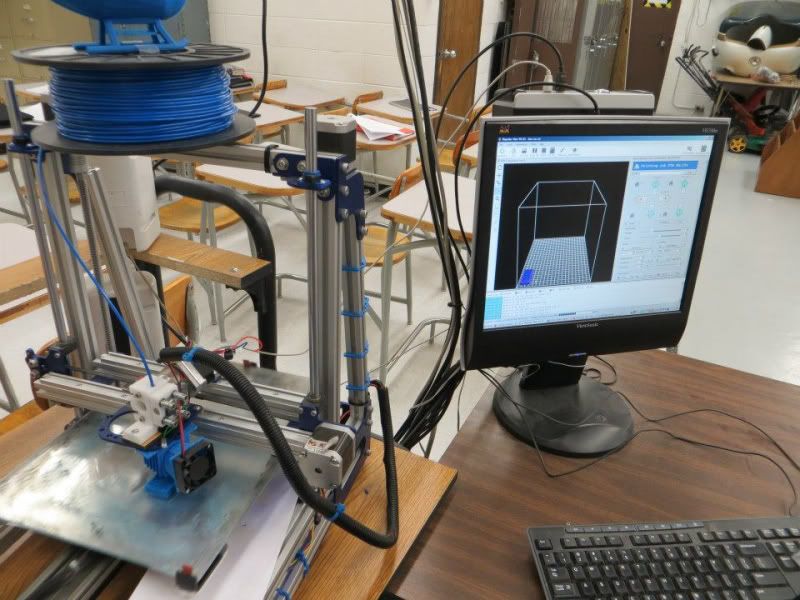

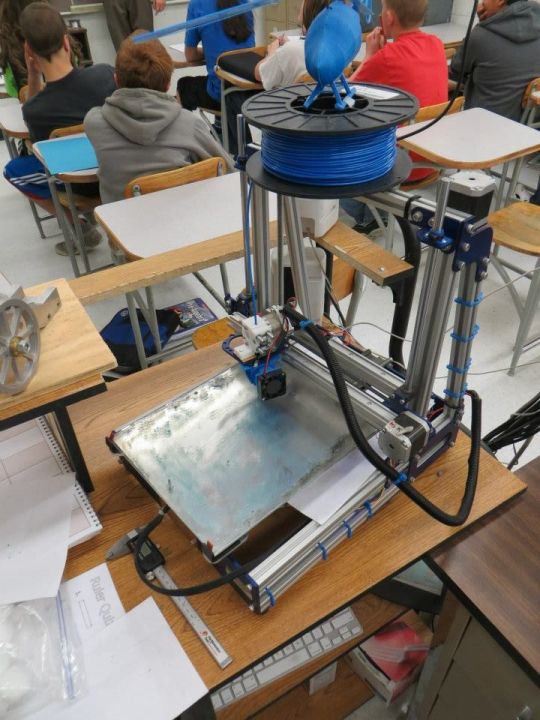

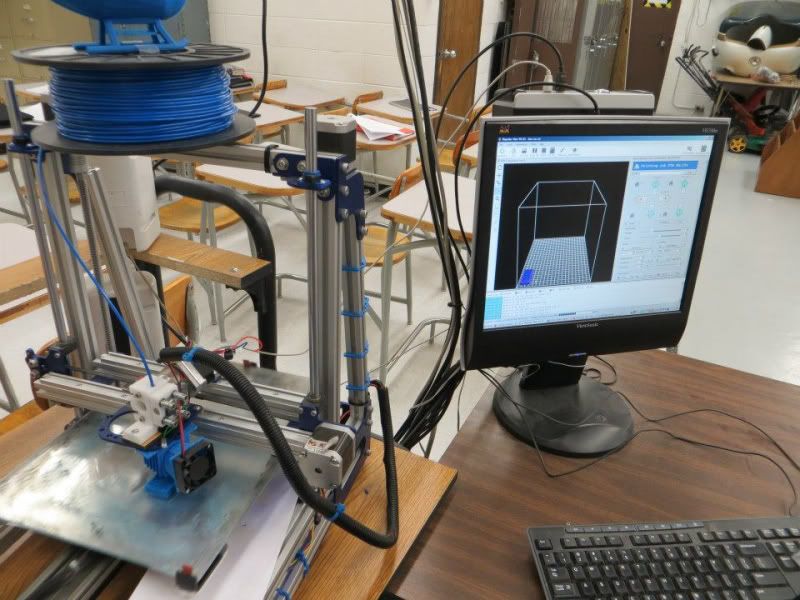

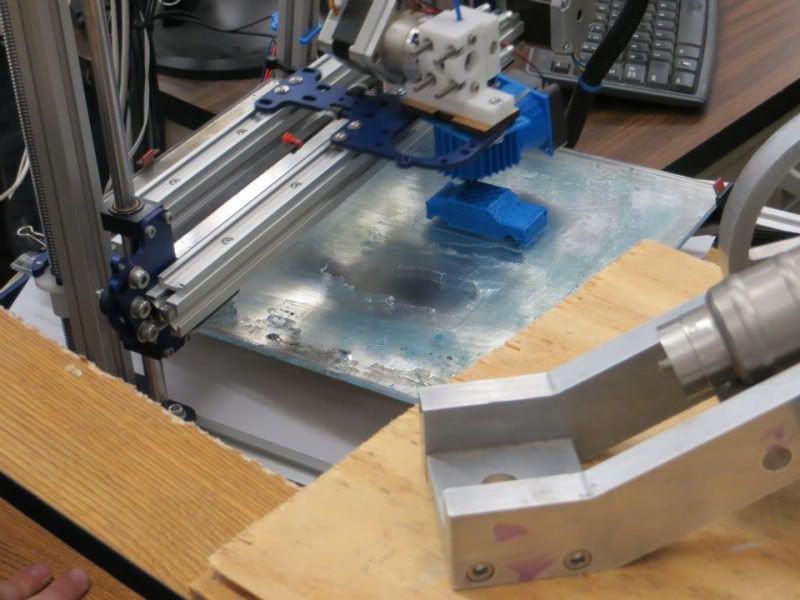

The printer... Y'all have seen it before it here it is in it's "home". Had to slightly modify the desk so it would fit.

The heli's final resting place.

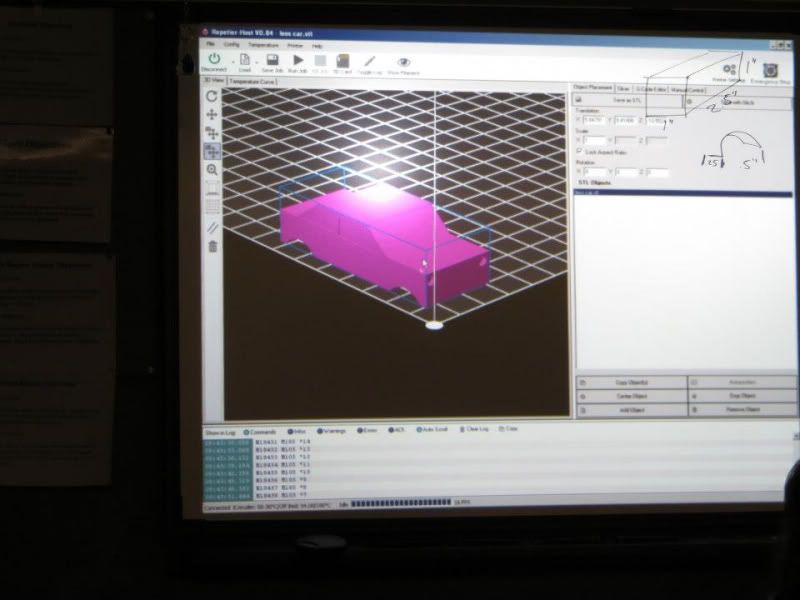

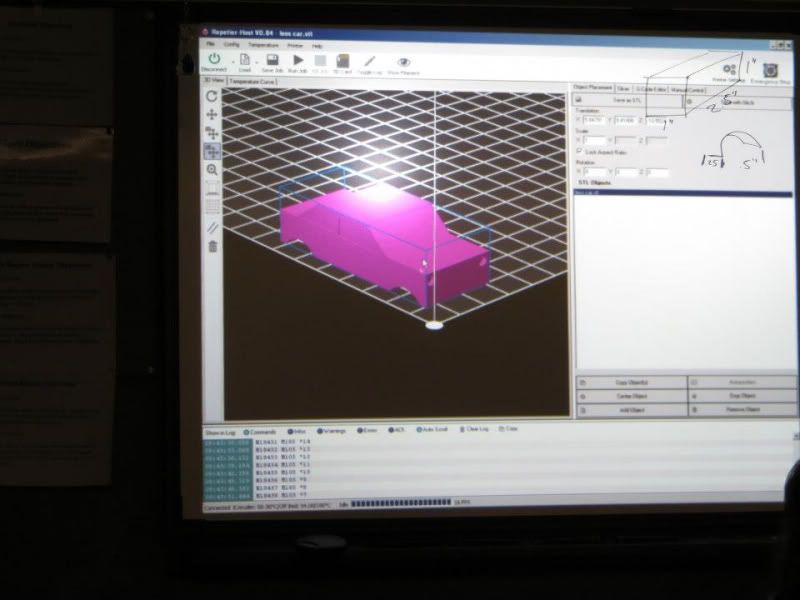

Edumication. Walked them through the process of exporting the file from

Sketchup as an .stl, repairing it in Netfabb, and finally loading and

positioning in Repetier.

Explained to them how Slic3r worked and showed them a few of the basic

settings, then we sliced. They were pretty impressed that we generated

18,000 lines of code for one simple car. It was fun to make them think

math for a bit- vectors / coordinates on an X/Y grid, and explain to

them a few different g-codes and how the computer interpreted them the

same way they do in their math classes.

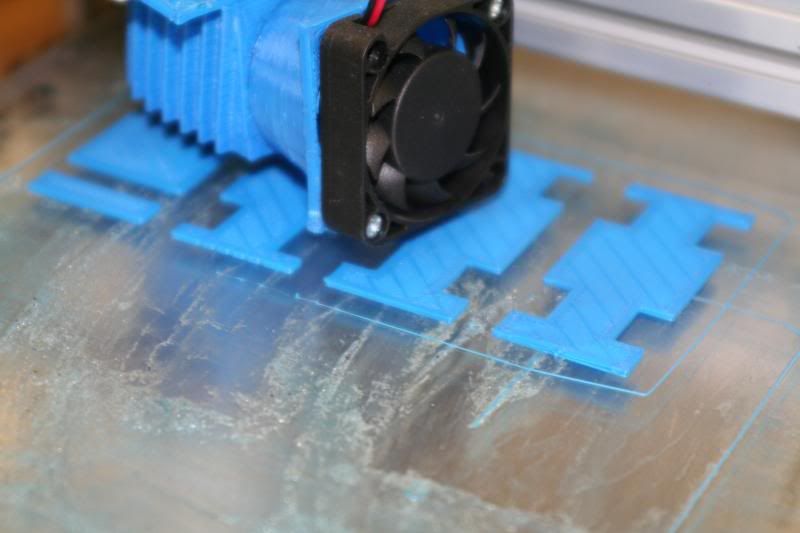

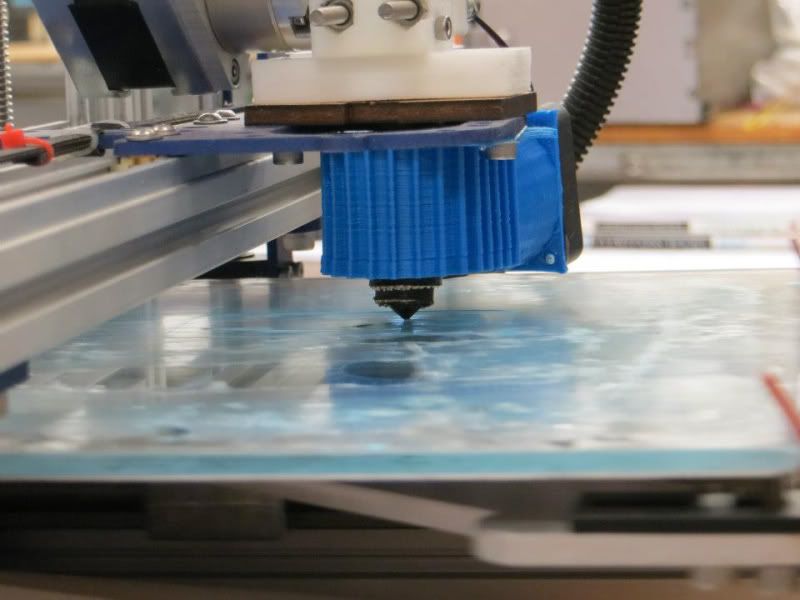

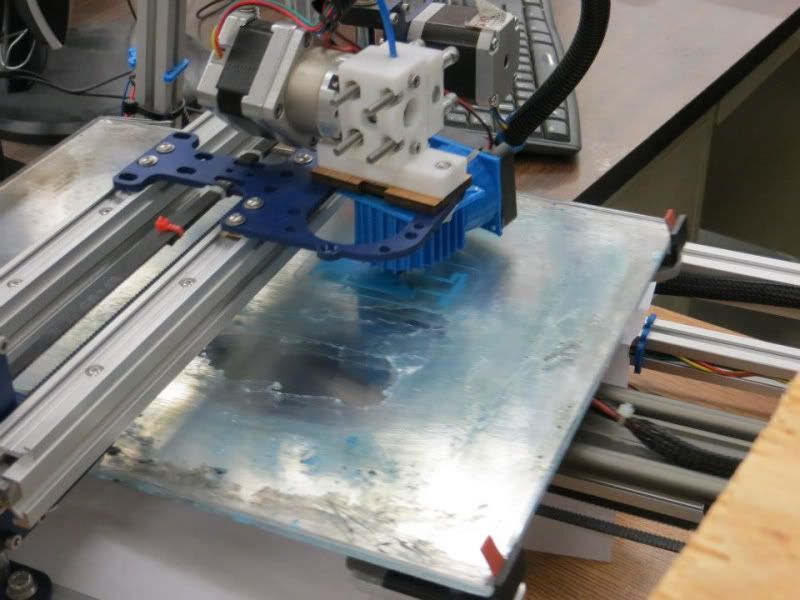

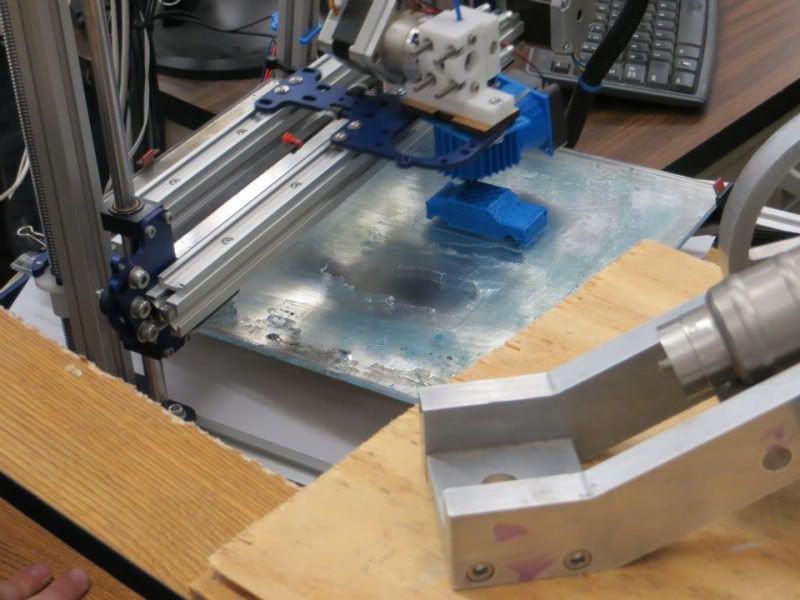

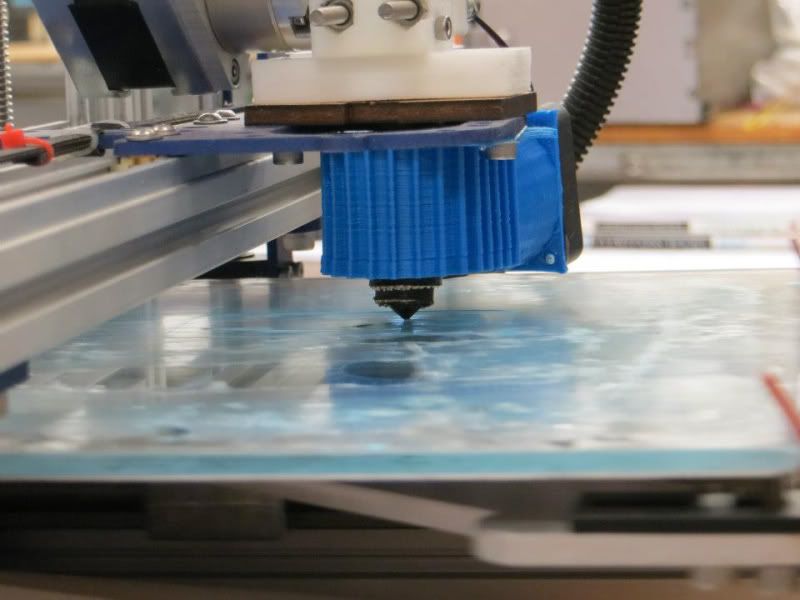

Business end of the printer all set up and ready to go.

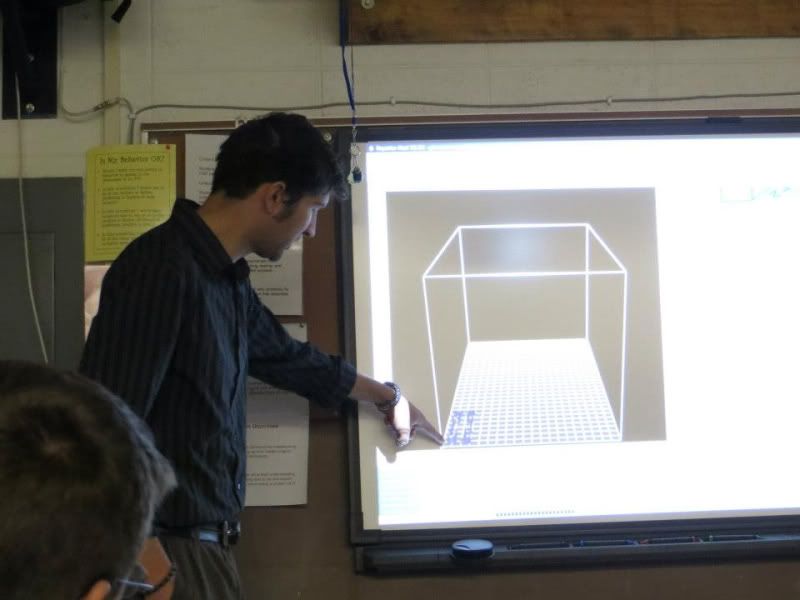

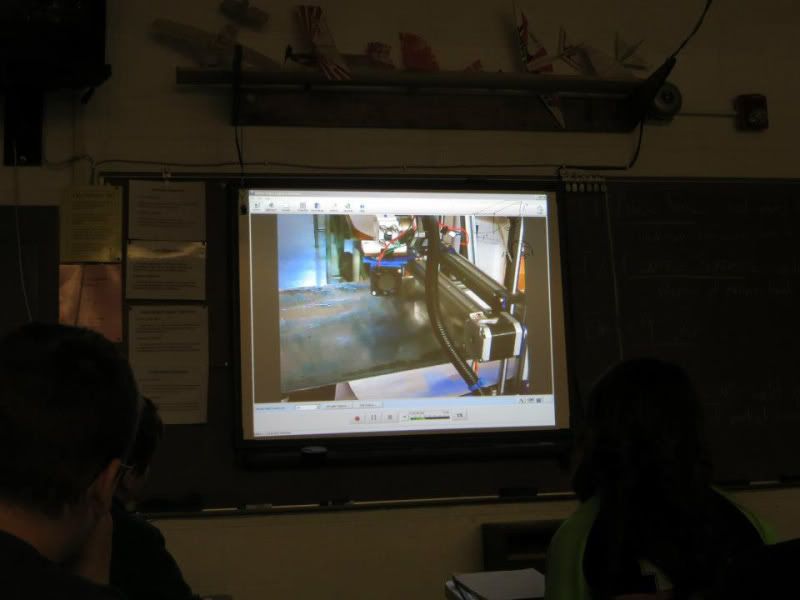

One of my most useful tools- a webcam, duct taped to a light arm. I

can point it anywhere (including my monitor) so they can see what I'm

doing up close on the screen without having to crowd around me.

What they see on the screen:

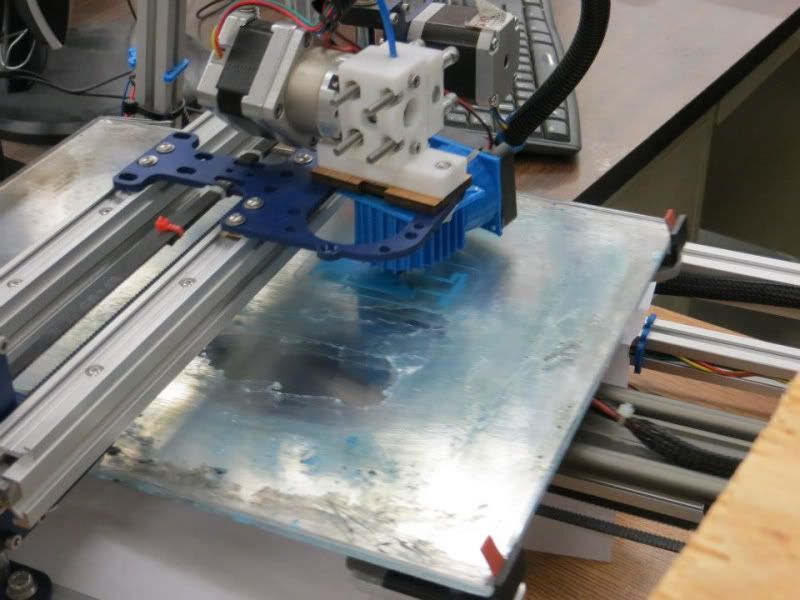

Annndd..... PRINT!

Not real great quality because I had the speeds cranked way up so they could see it finished during class. This print only took about 12 minutes- 10% infill.

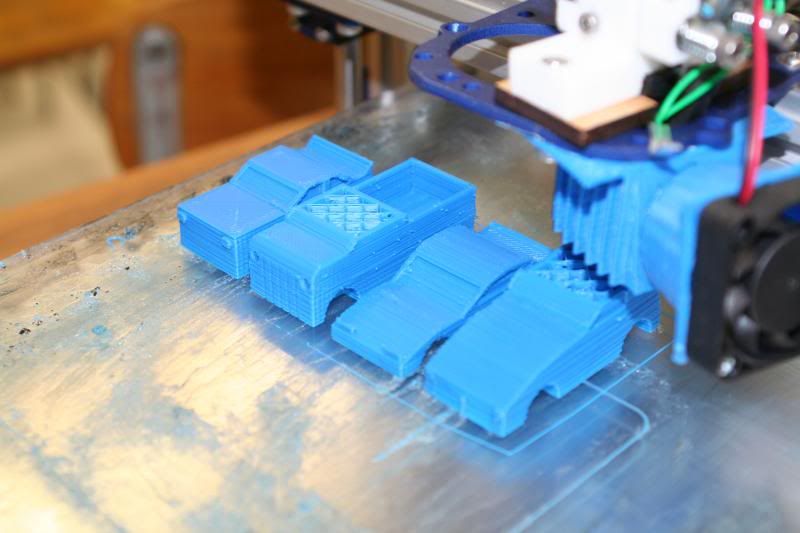

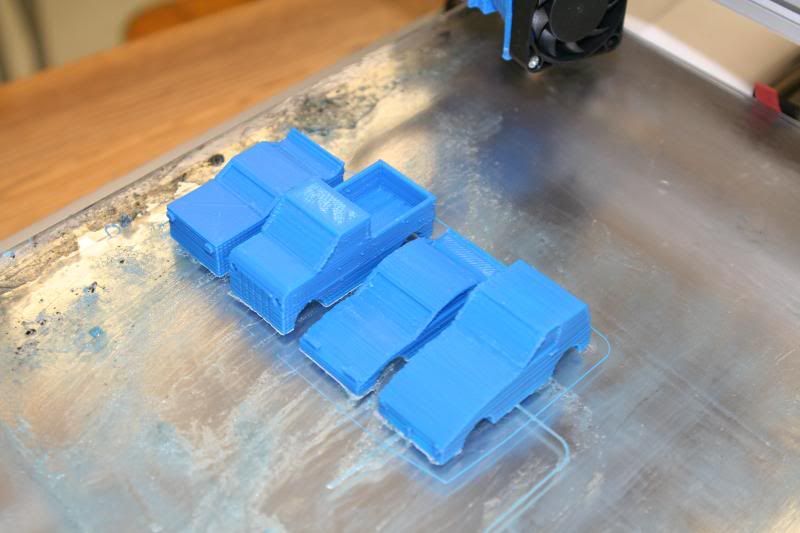

Explain some of the capabilities- manufacturing custom parts for Hotwheels.

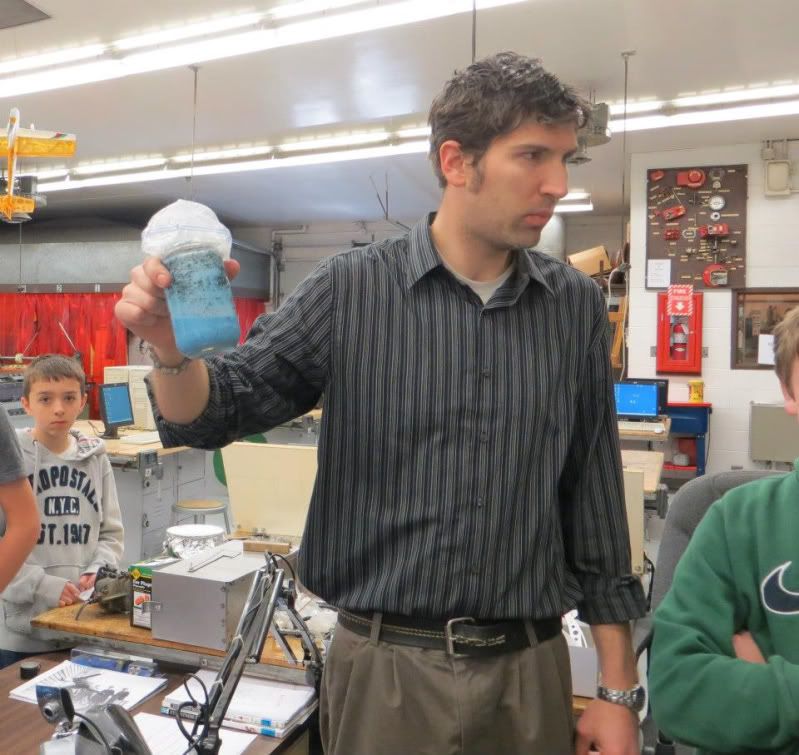

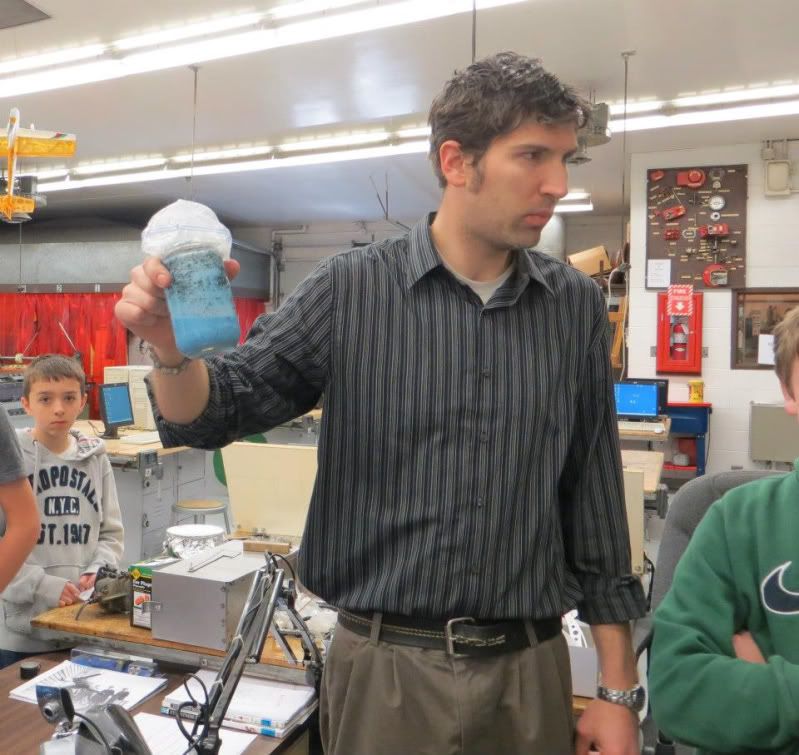

Yeah, this pic... "BEHAVE, or I shall turn you into this vile blue goo!"

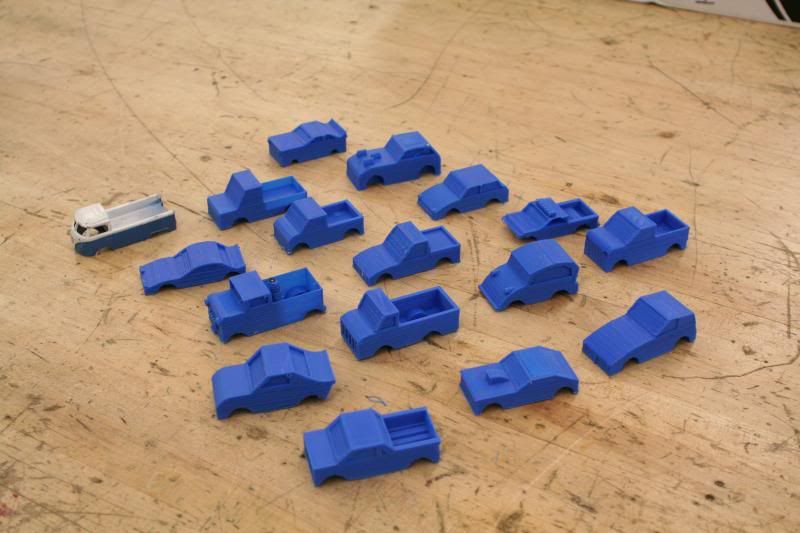

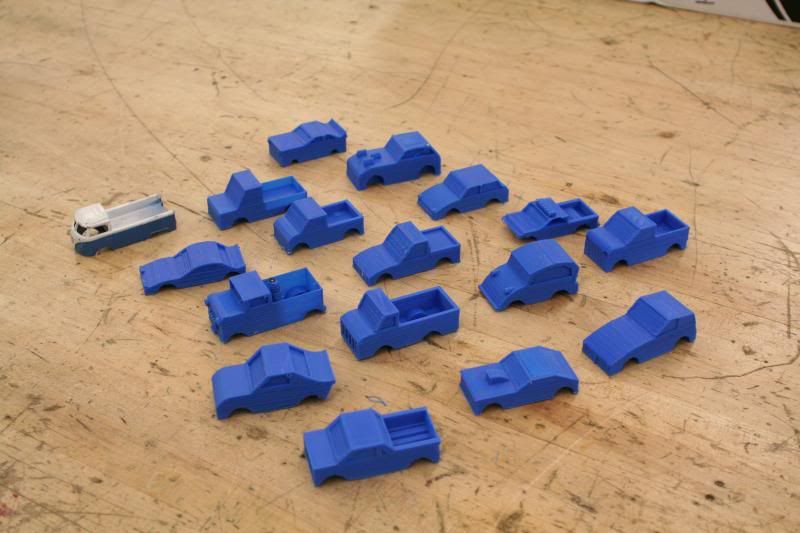

Got a bunch more done- up to 26. Have just a few to finish up and then we start printing wheels.

Print quality is much better on these but still getting some defects. Think its a combination of things, mainly the fact that the desk the printer is on tends to shake as the printer runs. Plan on doing some experiments there in the future.

The students love watching the printer run... We had a test on sketchup /

printers on Friday, which I haven't had a chance to look through yet

but one of the questions was about what they thought the future would

bring to the 3D printing scene. Kind of excited to see what they think!

I'm still impressed with the Mendelmax 2.0. I ran it over 8 hours straight one day and about 6 the next with no issues whatsoever. It's been a long process getting bugs worked out and everything working, and I have a ways to go still as I learn more and attempt new things, but the printer has been more than up to the challenge.

Makers Tool Works, job well done!

This oughta be interesting... Hoping to start a batch printing tomorrow, because we've only got a week and a half of school left!!!

This oughta be interesting... Hoping to start a batch printing tomorrow, because we've only got a week and a half of school left!!!