They are impressed so far, but I'll be making some changes.

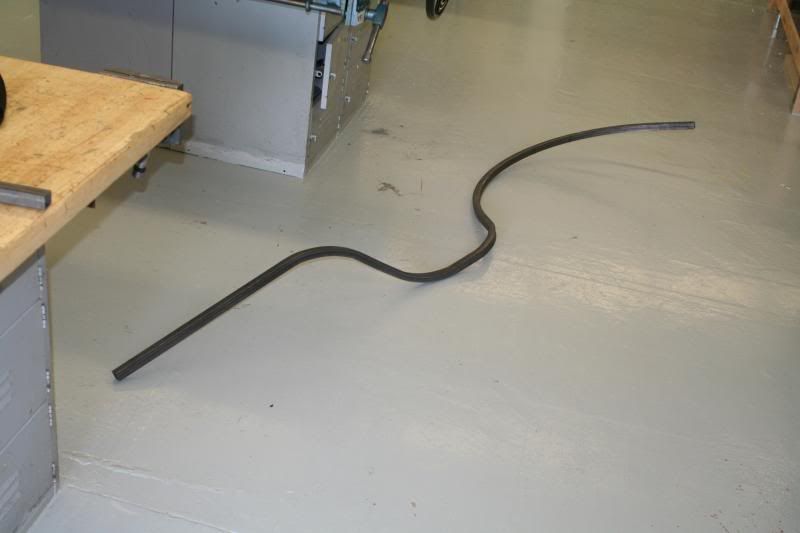

We got the leg pan figured out, came up with a plan for fenders, and worked out a way to shorten the tongue up substantially. In addition, they decided to make the tongue detachable from the rest of the trailer for ease of storage and also possibly in the future make it easy to convert to a stroller. Will be adding some blocks to the back also, so we can build a stroller handle for it later if we want to. When I cut the tongue, I'm also going to stand the seat up a little straighter as well.

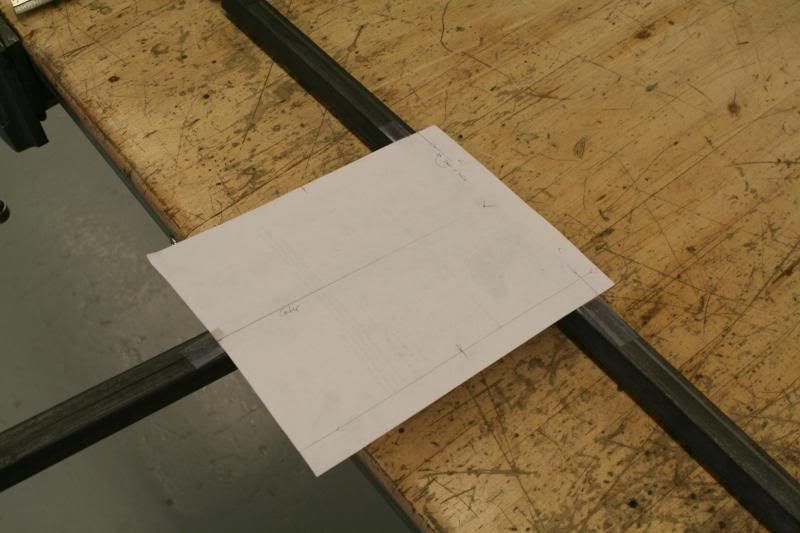

Started on the fenders one evening after school. Did some measurin, and drew this up.

Traced it on to some aluminum and added room for attaching it to things / strengthening with hems,

and cut 'em out.

I'm really starting to love my edge forming machine. Picked up some new Harbor freight tools that really compliment it as well. Here's one fender with one edge rolled so I can rivet it to the top:

Curled it up pretty badly. No problem- take it over to the shrinker/stretcher and straighten it out!

Way better! Time for a test fit.

The top piece was just a test- it will be longer to match the side cover and I still havent decided if I'm going to do the little rooster tail on the end. The front curve will blend in to the side piece, and the beads in the top will change- have to leave room for the rivets.

I will make a straighter version for the back side, and they will get holes punched so they fit over the axle. Will have to add a bracket and some support to the back side but with the bends its already pretty stout!

Punchin holes the old fashioned way!

Still have to rivet the top on to the other side and make both inside pieces.

.

.