Maker Gears instructions were pretty good, and can be found here: http://www.makergear.com/pages/stepp...r-instructions . There were a few things that I found confusing, mainly putting the larger pieces together, but overall its pretty straight forward.

Start by assembling the hot end. This is covered nicely already in the link above, so I'll just include a pic or three of what I did.

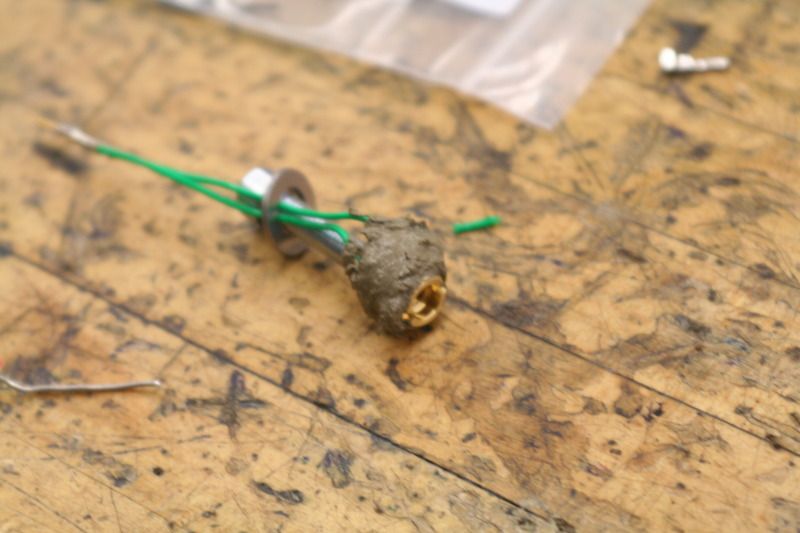

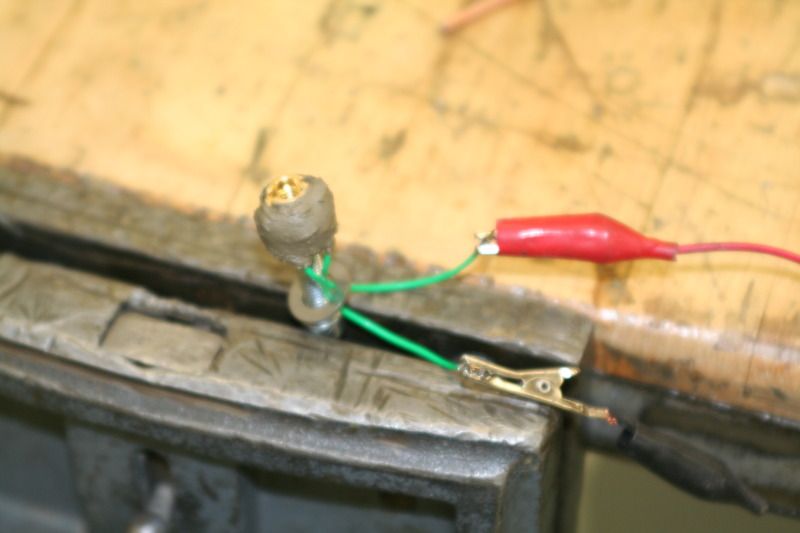

Start with this little ball in the center, attach clips to it, attach wires to the clips, and solder. The little ball is a piece of brass with nichrome wire wrapped around it and a first coating of ceramic already applied.

Thread it onto the included bolt and washer (these are only used to hold the pieces together while putting the paste on).

Apply goopy paste.

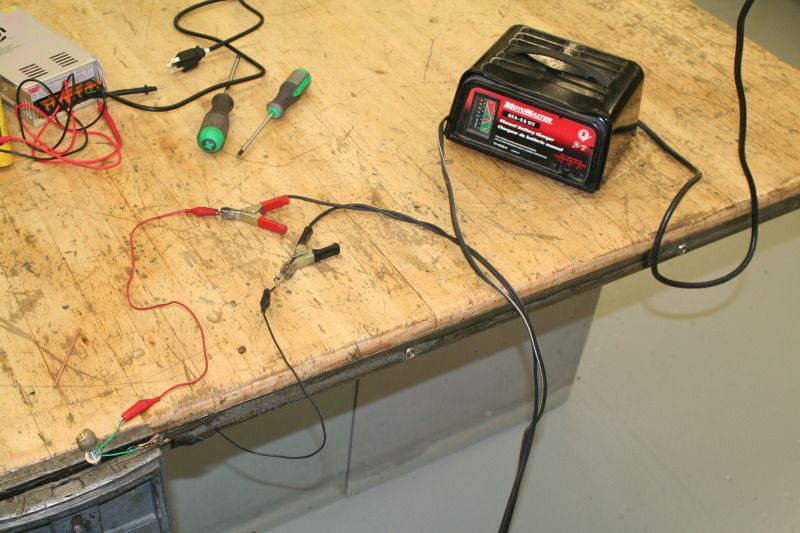

The paste looks ugly but when you cure it it smooths out nicely. To cure it, you have to zap it with 12 volts for 2 minutes to heat it up, then let it cool, then repeat several more times. The heat cures the ceramic and hardens it apparently...

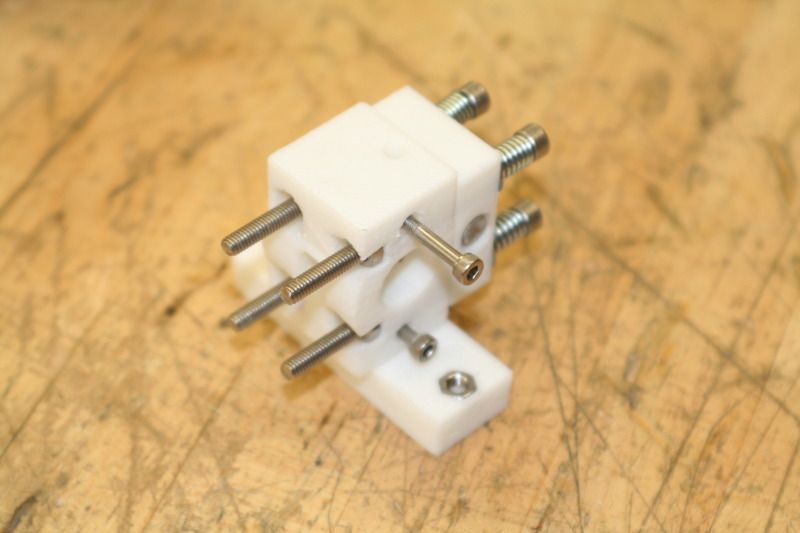

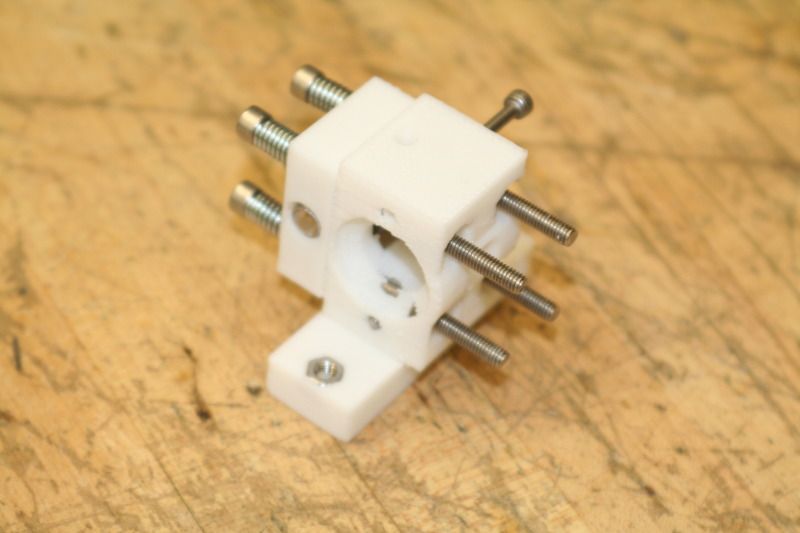

Putting it all together was a little confusing to me, but it was pretty easy to figure out.

The directions for this part were pretty straight forward.

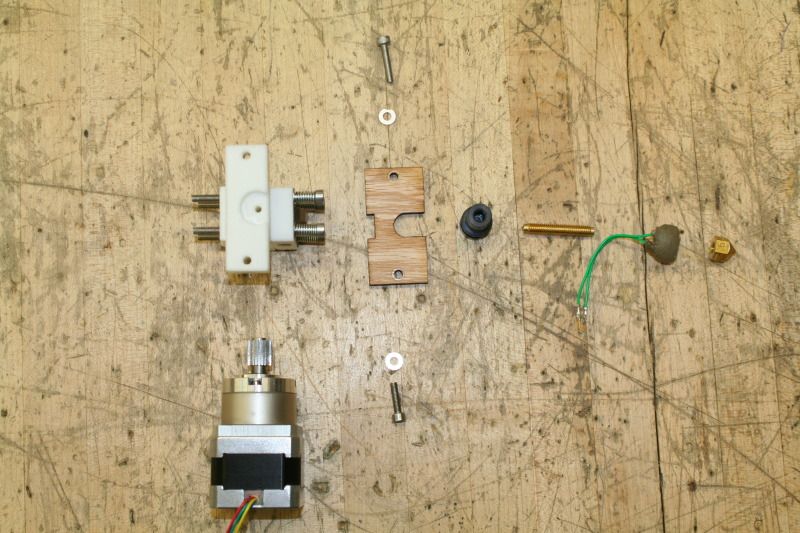

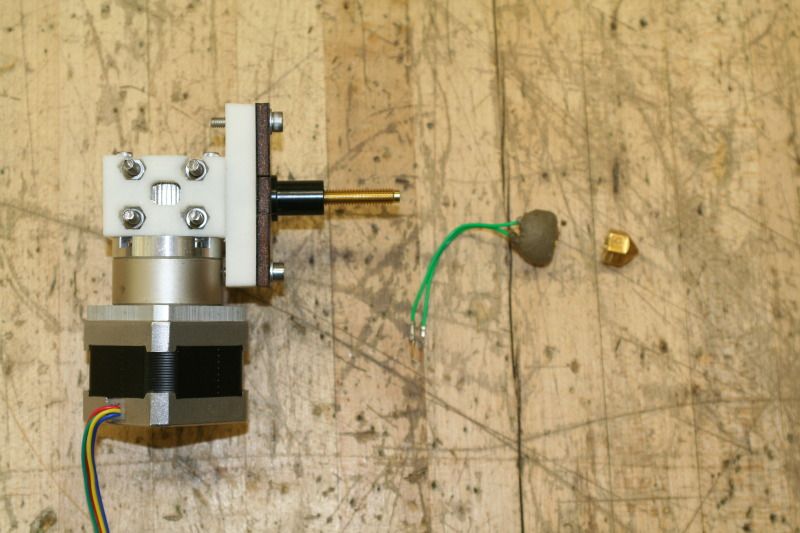

On their website they have about 4 different choices of assembled plastruders, and none of them seem to match exactly what I have, so here's what I figured out. Here's all of the parts in an exploded view.

Follow the pics, its pretty straight forward. The black plastic tube gets slid into the notch in the wood. Notice the screw in the bottom of the pic is shorter than the one in the top... Thats important in a minute.

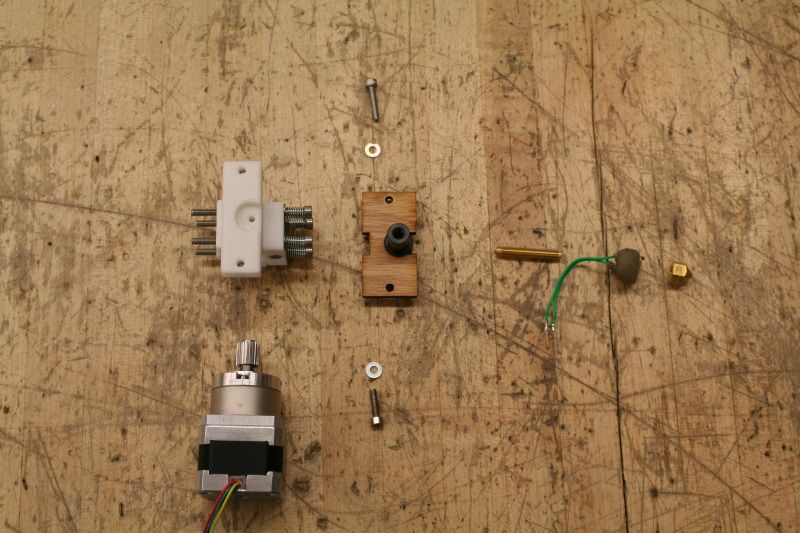

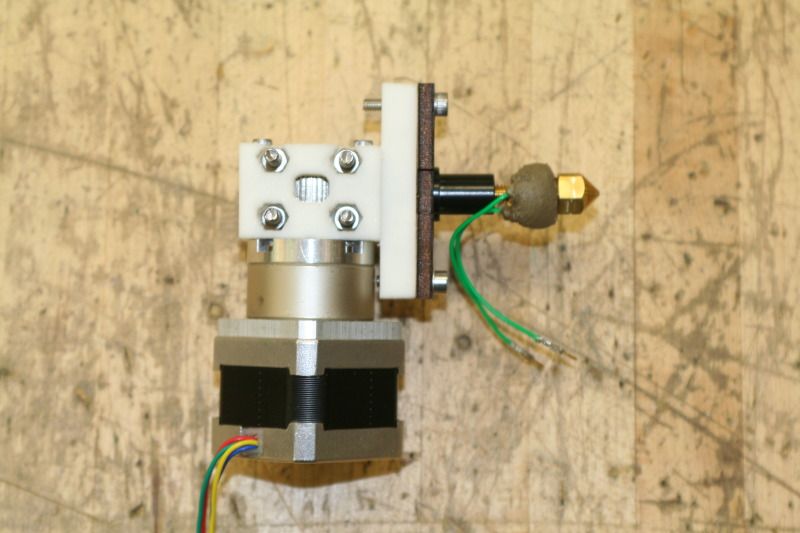

The wood plate is attached to the plastic extruder block.

See the shorter screw? Don't know why they didnt just use 2 short ones...

Install the stepper motor. The one screw is short so it doesnt hit the motor.

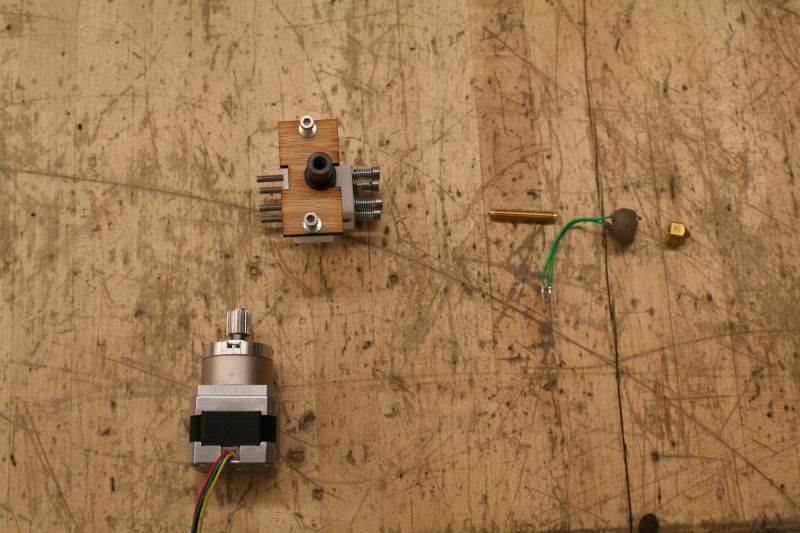

The rest of these pics just show the innards of the hot end. Once the hot end is complete, its not really something you take apart. It's designed so that you just take the wood plate off, and everything from the black plastic tube to the nozzle comes off as one piece.

Still needs the temp sensor and covering installed. Plan on letting the ceramic cure overnight, and zap it a few more times tomorrow just to be safe and then finish it up.

Thats where I'm at now. Tomorrow I will finish the hot end with the temp sensor and wiring, and them I'm out of stuff to do until the rest of the printer shows up- probably not until the second week of February.

I figured it would be a good idea to record the time I've spent on this. I'm only going to count the time I spend working on the printer- not counting time spent sourcing parts, scaring up funds, figuring out software, etc.

So far, with the assembly of the plastruder and wiring of the power supply I'll call it an even 2 hours. This DOES include time spent re-reading the instructions and double checking I was doing things right.

Time today: 2.0 hrs.

Total Time: 2.0 hrs.

No comments:

Post a Comment