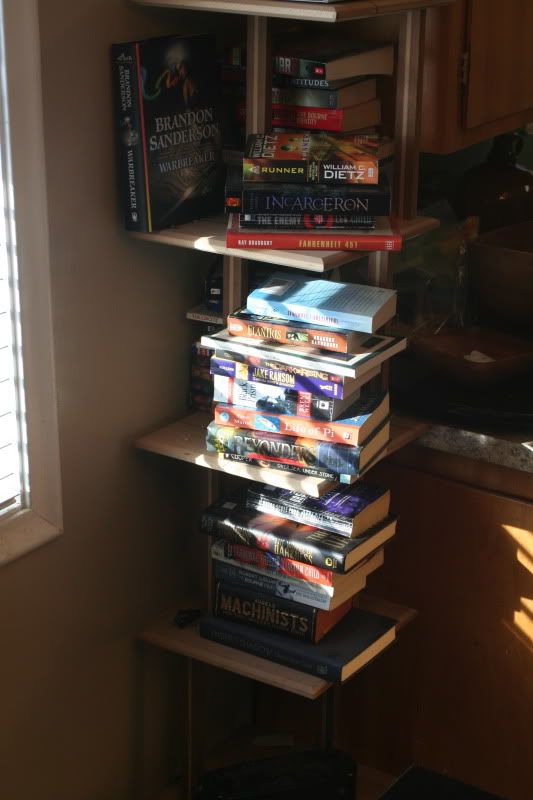

The top shelf have been read in the last couple of months, the next two down are on the "to read" list. If only there was just this one bookshelf...

I also went in to play around in the shop for a bit this afternoon. Got my grades mostly done for parent teacher conferences coming up and mucked around with the TIG welder a bit more. Spent some time trying a few different things I've read about, and am starting to get a little success!

Some great resources for welding:

Adventure rider welding thread- http://www.advrider.com/forums/showthread.php?t=210053

Welding Web- http://weldingweb.com/

I could spend hours on that second one. Who'm I kidding, I could spend hours on both of them. Below are a few of today's tungsten's. A few people suggested I had my current set too low, so the one on the left was at about 150 amps, AC smooth, 1/16th tungsten and filler rod. Didn't last more than 5 seconds. The next was turned down to about 100, the next 80, and the last two are at 65. I switched to 1/8 rod on the last tungsten and managed to keep it going for a long time, although I probably *should* have changed it because it got contaminated...

The results. Might not look like much but it is getting better (I hope)! It can be tough welding over top of junky welds but they are starting to smooth out. Finally getting the dip/jump rhythm. The thicker rod makes it a lot easier to dip/jump for me.

I'm also starting to get the hang of telling when the base metal is too cold or hot to weld. To cold and the puddle just won't carry and the rod beads up on top. Too hot and it sinks in and looks "filmy" after it cools. Just right- you get a nice puddle that is easy to carry, the rod melts nicely, and the finished weld is nice and shiny with the "stacked dimes" appearance.

Three or 4 more years of practicing every day, I might just be able to weld aluminum. Then I can start trying the thin stuff.

2 comments:

Old school TIG on aluminum and magnesium: Assuming you have a foot pedal,ball the tungsten by putting welder on DC+, striking an arc and then increasing amperage until tungsten flares. Reset machine to ACHF.

Set torch on workpiece resting on gas cup with tungsten clear of basemetal (about 45 degree angle). Initiate arc and roll torch upward until it's about 10 degrees back from vertical and establish arc length (1/16" - 3/32"). Bring amperage up slowly so as not to "burn" aluminum. Once you have a puddle established, start traveling. Maintain a 90 degree angle between torch and filler rod. If the torch has too much lead angle it will melt the filler rod before it has a chance to reach the puddle - big globs on the plate. Not good. If the aluminum was clean and the amperage was correct, the weld will be bright and shiny. If too cold, dull finish and will look like a worm laying on top of the plate. If too hot, weld will get wide with no visible build up.

Remember the reason for a foot pedal is because aluminum transfers heat much differently than steel. When you first start, it's carrying the heat away rapidly, then it's just right, then it's too hot. Thin gauge material that could be just a few seconds.

I made a couple of short videos last year on TIG and Oxy-Acety cutting. I need to figure out how to put them on my blog. If you're interested in them, I could burn a copy of the disc and send it to you or send you the files somehow.

Thanks for the info! Most of the welds pictured were shiny before I wire brushed it again. I don't have a foot pedal... Any idea how hard it would be to wire one up on my old box that was never intended to have one?

I've definitely noticed that the base metal has to be at the right temperature, and since I don't have a pedal this means starting slow, gradually moving faster, and then waiting until the metal has cooled enough to do another pass. Had the chance to play with a TIG set up with a foot pedal about 2 years ago, but I didn't have hardly any seat time.

Would love to see your videos, any chance you could post them to youtube? You could then link to them from your blog.

Post a Comment