I had a conversation with a few other guys about printing with metal. I jokingly mentioned that solder has a lower melting point than the plastic we use. Apparently, its already been tried with mixed results. Then I got to thinking... What if?

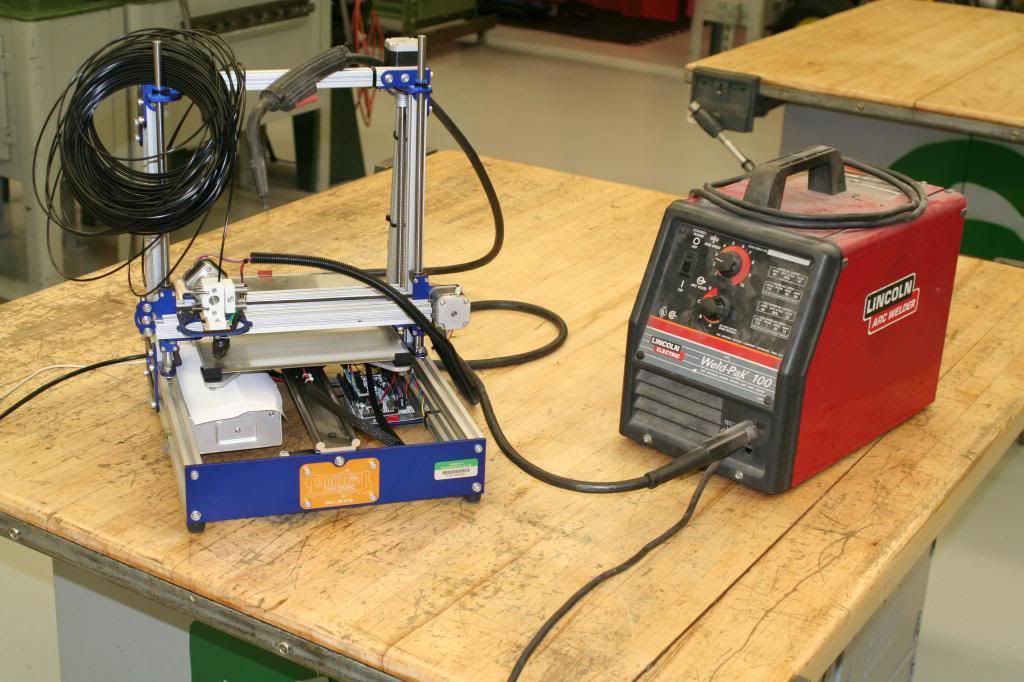

Obviously, the welder is just sitting there. I played around a little and was able to get a few semi decent ultra tiny beads out of the welder. No penetration whatsoever, but I think with some tinkering and some consistent feeds, I could get beads about 1mm wide and maybe .25mm tall. The trick then will be getting the printer software to think its melting plastic. I *think* I have a few ideas on how to make that work. Maybe a solenoid or two to activate the wire feed and welder. It would have to have a sacrificial base plate, but that could probably be cut off fairly easily after the fact if needed.

Am I crazy? Probably. Will I ever actually try this? Maybe. I'd REALLY like to, but you know how life goes... If you are interested in reading about another's attempts at printing metal, check this out:

http://blog.reprap.org/2011/06/new-approach-to-printing-metals.html

http://blog.reprap.org/search?q=metal

And a cool video with metal printing:

In the meantime, a few shots of my latest prints.

No comments:

Post a Comment