This is work I had done a few weeks ago, but havent had a chance to show y'all 'till now. I had arranged for a day off but then the plans we had for the day fell through so I was left home, alone, with some tools and supplies...

Add sewing to the list of things that I'm not all that great at...

Lets see what I can do with all of this crap.

Today's helper: Slinky.

Measurin an markin:

Turns out sewing zig zags are a little tricky. Meh. Good enough for now.

Really tricky getting the ends on.

Fitting it up.

Add some bling.

Done for now.

Turned out about how I envisioned it, which I *think* is a good thing. Still need to figure out a hinge for the cover on the back, the tail light, and some sort of mount to attach the whole shootin' match to the bike. I've got a pretty good idea how to do it, just need to DO it. The sleeping pad cushion is surprisingly comfortable too!

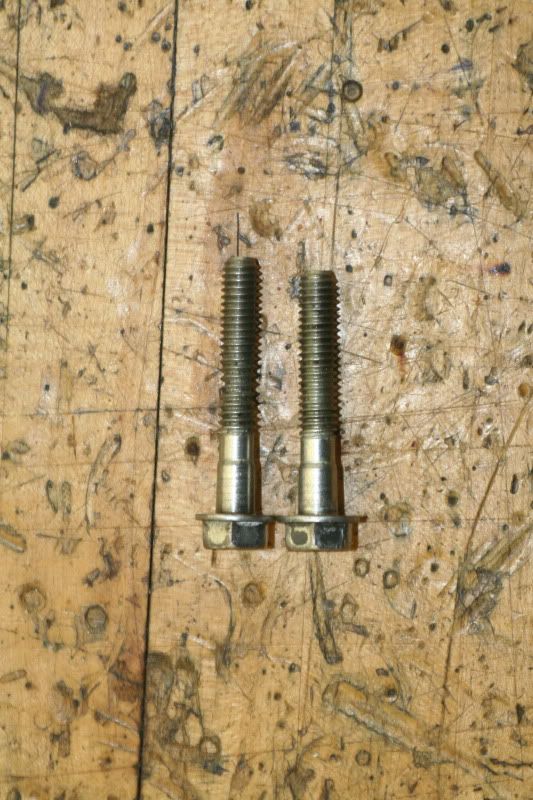

Fabbed up some brackets for the seat.

Made some rubber mounts out of stoppers to absorb some of the vibes...

And made a little side cover to kind of tie in the tank and seat. Not sure it will stay, have a few other ideas in mind as well, but this is what I've got for now.

Its just sitting in there loose in the last pic. I will probably have to remake it when I get the tank finished to make it match the lines.

So that's where project POJ sits as of now. Been so long that I think I've forgotten how to TIG weld. I've been on the hunt for a nice welder, but havent found anything in my price range (free or close to it. Yeah, that'll happen.) yet- have a few more "junkyards" to check out though. I did pick up a tail light to stuff in the seat bump and have tinkered with that a bit but still haven't decided anything for sure. More in a few weeks... I hope.