Previous to this expereince, I had ZERO time playing with 3D printers. I did get an Associates degree in Manufacturing Engineering like 10 years ago, which had a fair bit of CNC experience, and that helped a bit. There is litterally thousands upon thousands of pages of information out there on the internet, and many different resources for setting up your own printer.

What does all this mean? Well, I don't know how qualified I am to review the Mendelmax 2.0, but here's my take on it. Given my background I would consider myself as one with great skills when it comes to the mechanical end of things, but only mediocre when it comes to the electronics / software end of things. I will admit- this was a HARD project for me. It took a lot of time and I had to do a lot of research and trial and error to get prints. I do feel though that as this specific printer moves from the beta testing process into a more refined package for resale, many of my headaches will have been eliminated. Many of the issues I have had have already been adressed, and as more people build and use this printer the support group and information will expand exponentialy.

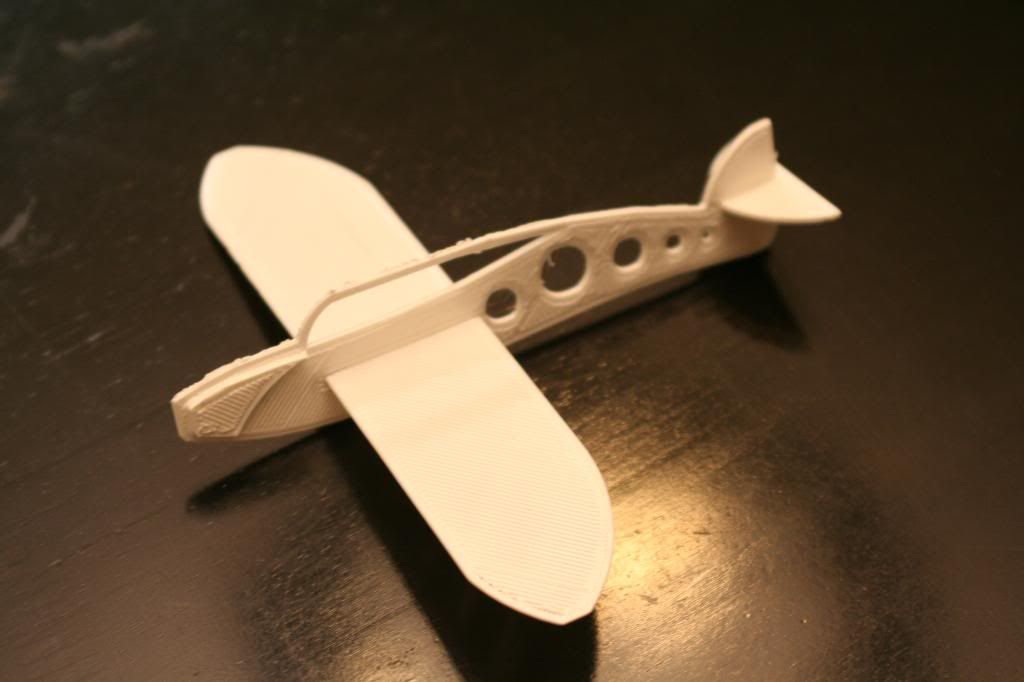

As for print quality. Again, I don't have much to compare it to, so here's my take. From what I have seen, the quality coming off of my printer is excellent. There are hundreds of varialbes that affect the quality- type of plastic, size of nozzle, extruder, heated bed, design of parts, and on and on. In addition to the physical factors, it does take some practice and some skill to get the printer aligned and calibrated each time, and to know how to design prints to be successfull. It's all part of the huge learning curve. Again, thankfully, there is a lot of info and a lot of people out there willing to help you become successfull.

I full intend to use the heck out of this machine in the classes I teach. I don't see any reason why it isn't up to the task of running just about continuosly day in and day out in a middle school setting. Sure, things will probably wear out or need adjusting, but it's a well built, well thought out design that can only get better- that's the beauty of REPRAP's or REPSTRAP's- everyone can littlerally print their own improvements. Heck, I've already got an idea to adapt some ideas from a MIG welder to my extruder to make it much quicker and easier (without tools) to change plastics.

Can't wait to see where this thing takes me. For now, we'll call the assembly and testing done. Keep in mind I will still have to do the z-axis update when it shows up, and I still plan on doing a lot of posts here about how to set up prints, slic3r settings, different plastics, and other little tips and tricks I've picked up doing this.

SO. Lets call it an even 18 hrs. to build, test, and get some decent prints off of this printer.

I feel now that I've done it, this could be DRASTICALLY reduced- I think much more reasonable estimate should be 5-10 hours for the total newby, and possibly quite a bit less for the experienced builder with all the tools and know-how from previous builds.

What would one of my posts be without a ton of pics?!

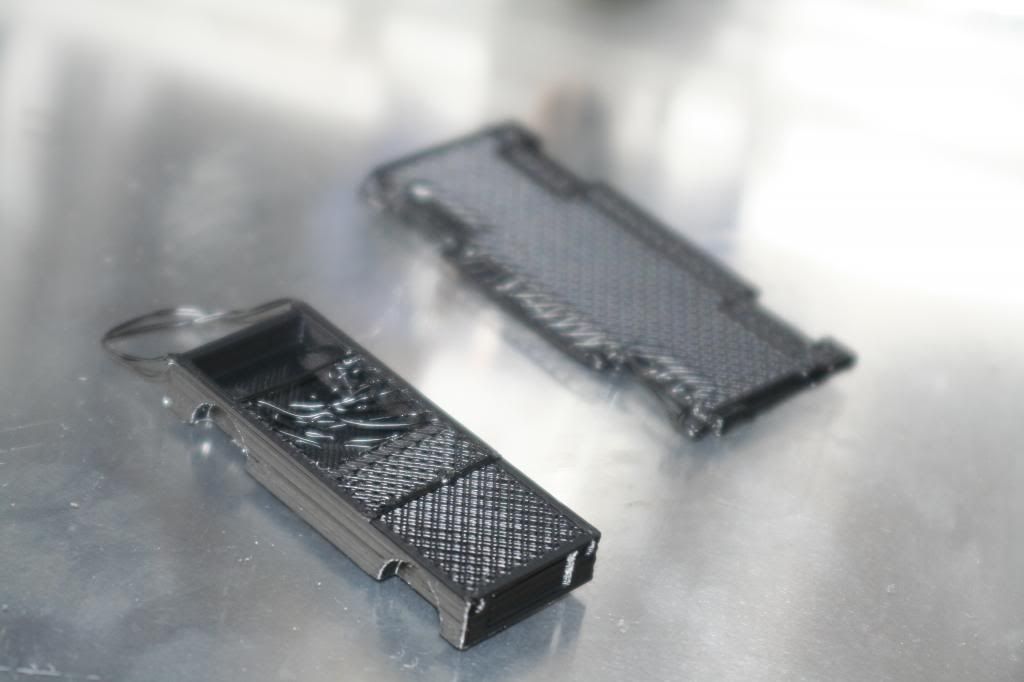

Some bling, both from Makers Tool Works and the school district...

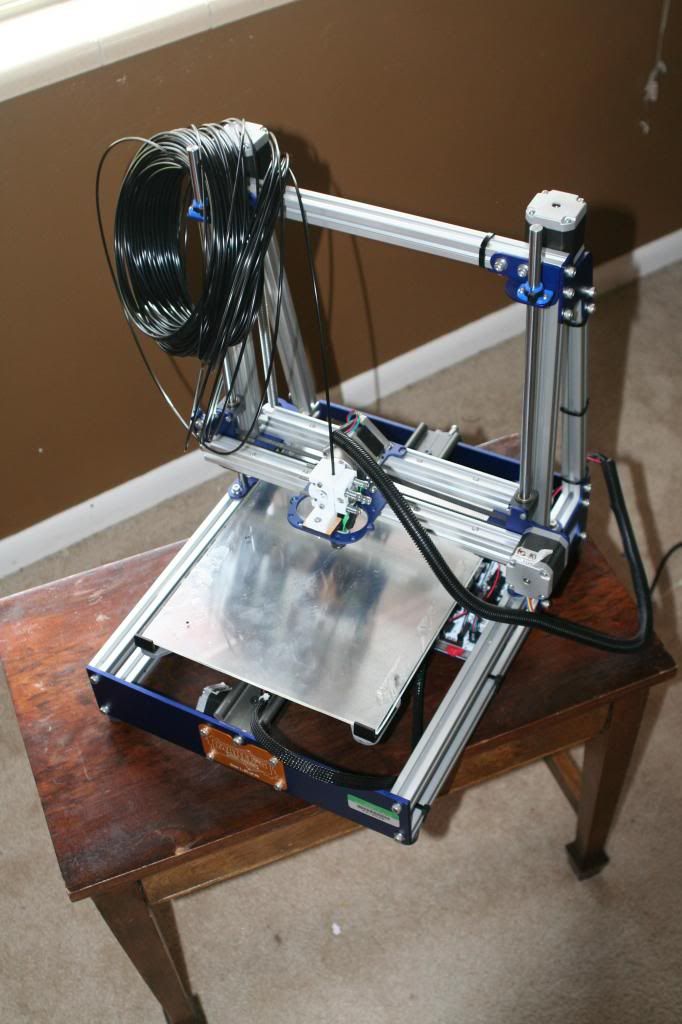

The "finished" printer. Still need to make a spool holder for the plastic among many other things...

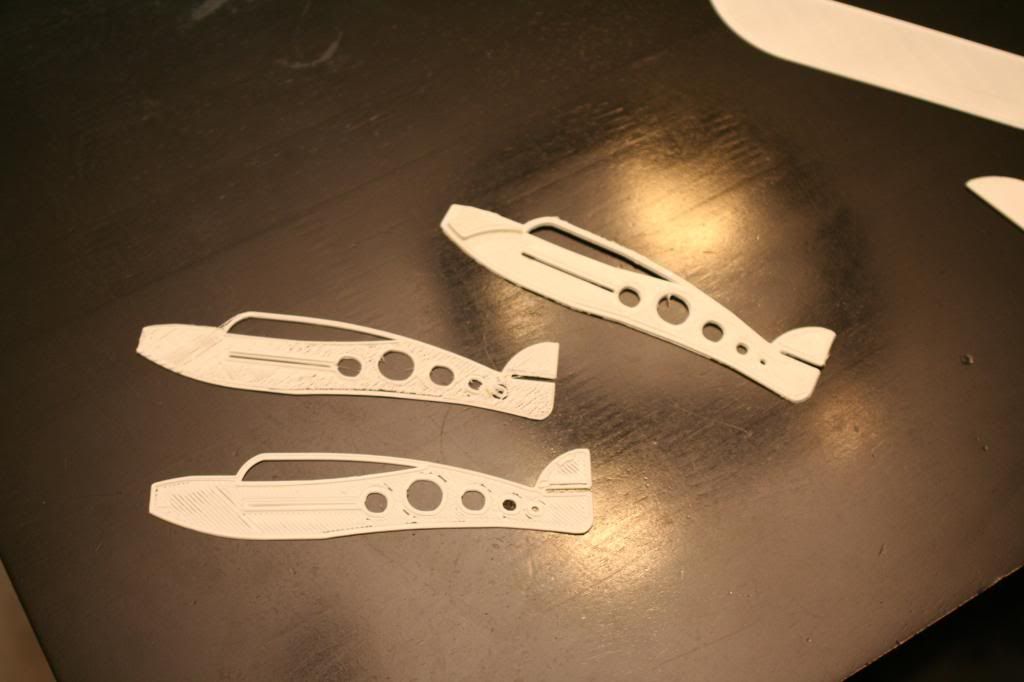

Several of my trials and errors.

Kids sure love to watch it!

1 comment:

This is SO great! I love seeing your students huddled around the printer. I thought I was a dork for just sitting there watching with my son, so glad to hear you have the same issues.

Congrats on the completion; so happy that you were able to get this for your school.

Post a Comment