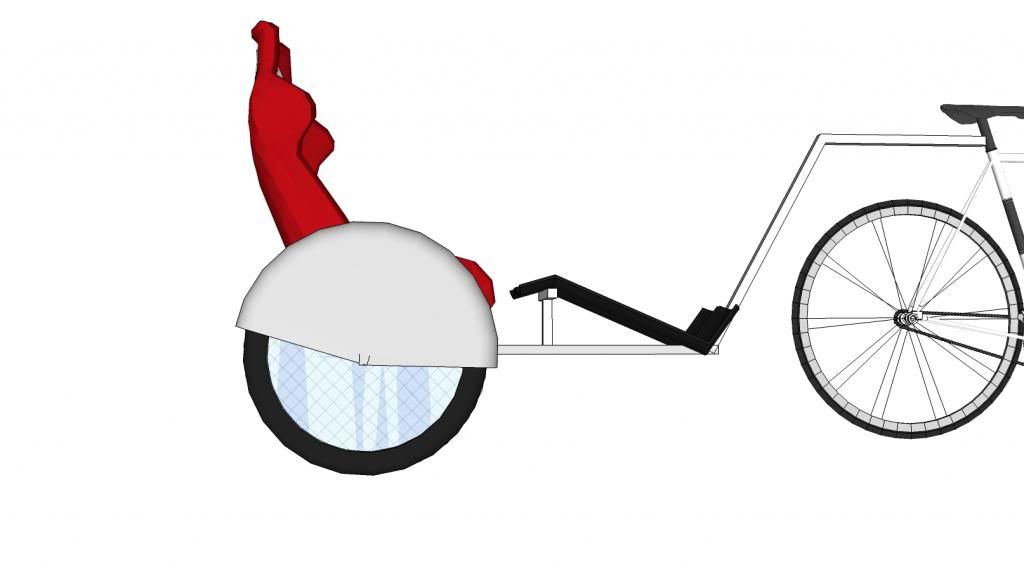

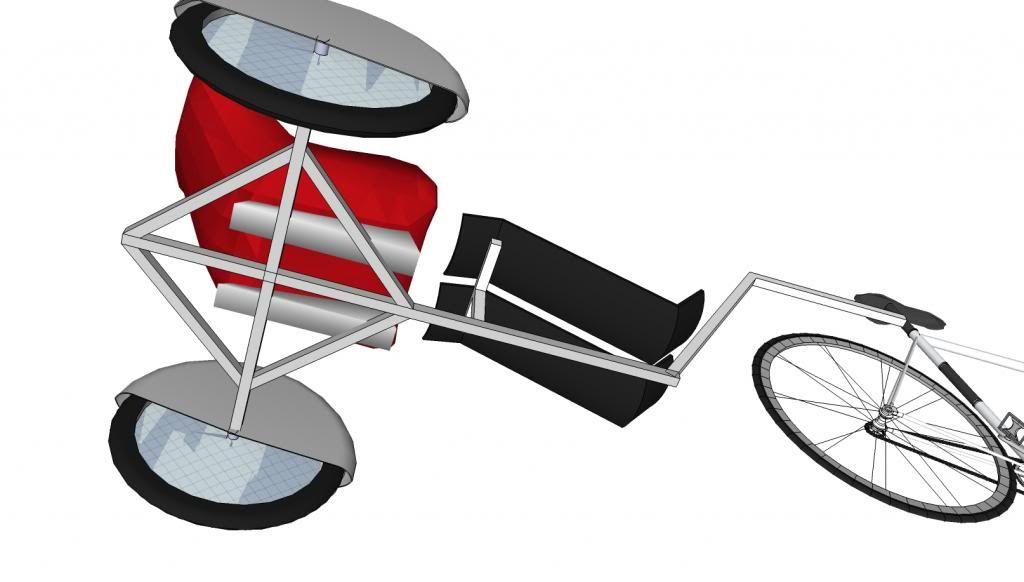

I've been kicking several ideas around for the last week and playing around on Sketchup. Here's what I've come up with. Remember, these are JUST ideas at this point, I really don't know much about bicycle trailers but I'm learning a lot along the way, and would love to hear it if anyone has any suggestions.

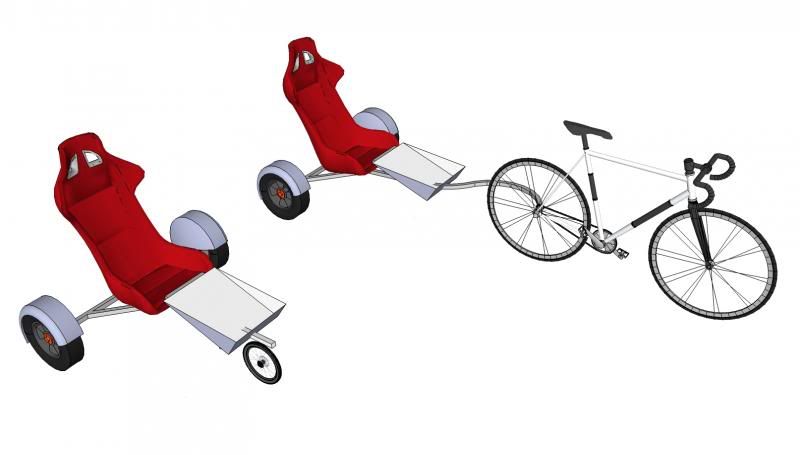

First sketches:

Real rough. As you can see from the next few sketches, a lot has changed. Kicked around a few more ideas, and discarded a few others.

Small tires, with a stroller version. Will be using bike tires, so this is moot.

Seat suspension. Probably won't be doing this.

Extended frame for adding a basket or carrying stuff.

Rollbar / pushbar for stroller.

Stroller, with detachable tongue / attachable caster wheel. Tongue stows under trailer.

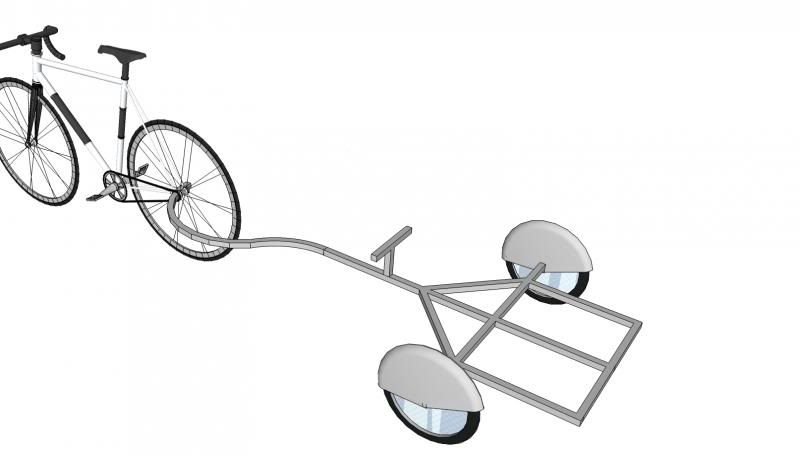

Other pics.

Keep in mind these are just design ideas... The trailer will likely be skinnier (this model has a 3' wide frame, will probably cut that down to 2') and change a bunch while building. Sounds like they really want me to build it, so I will, but there are a few other projects on the table and a few other things to iron out here first. May start on it over spring break, we'll just have to wait and see.

Current things we have decided on:

Bicycle wheels for sure. Probably 16", as I've read the smaller tires handle cornering forces better?

Low side mount tongue.

Some type of platform off the back to mount a basket or case of some sorts.

Fenders for the pull bicycles- Store bought.

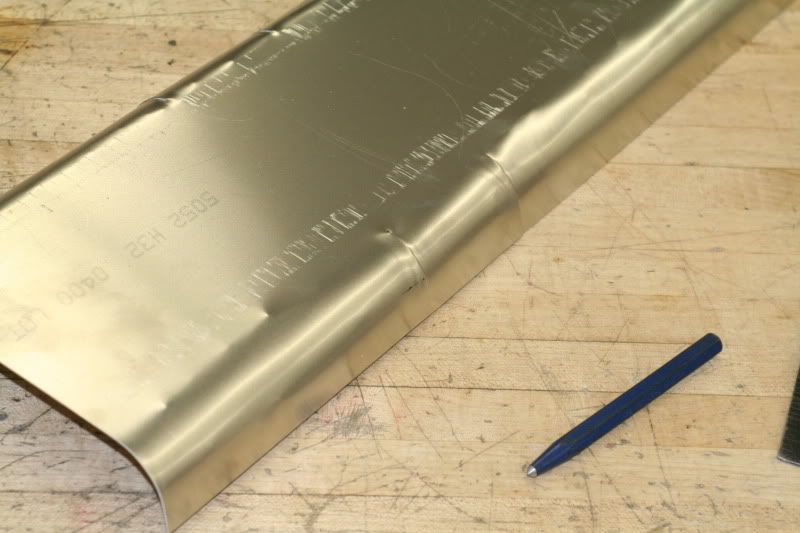

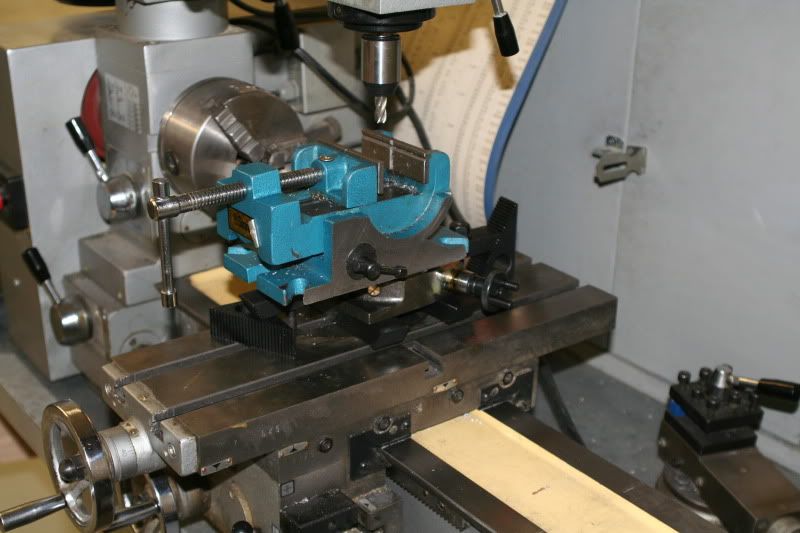

Fenders for the trailer- going to try hand making them out of aluminum sheet, but no cover on the outside.

Rotomolded racing seat from JEGS, with a 5 pt harness.

Leg board most likely also hand made by me out of aluminum sheet.

Things they seem to maybe want:

Seat suspension

Stroller castor / removable tongue

Powedercoated frame.

There you have it. I want to try and keep very little weight on the tongue, so the seat position will likely move back. The axles will be 5/8" rod welded to the top of the frame crossbar to lower the center of gravity more. I will probably have to build some type of bracket behind the seat to mount the safety harness too as well.

Anything I'm missing? Or, I know I'm missing about thirteen hundred things, wanna enlighten me on a few?!